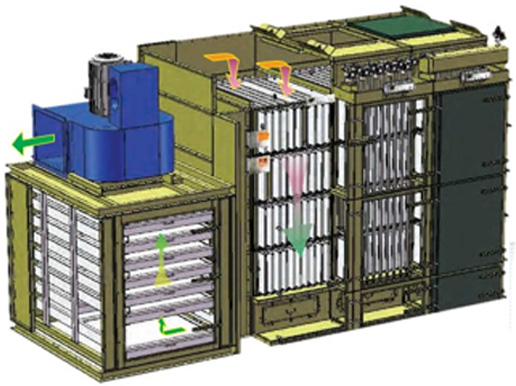

introduction of contaminated air

Heavy dust hits the bag filter and falls, fine dust/dust adsorbs on the bag filter

The adsorbed fine dust is desorbed by compressed air and dropped into the sludge basket

Purified air enters the A/C Tower

Purification of remaining gases/smells from nanocubic activated carbon

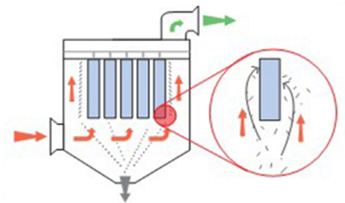

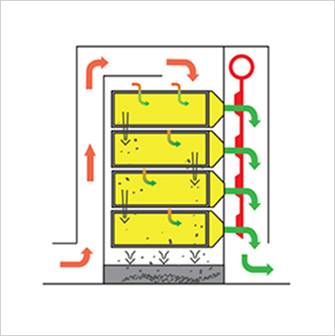

OLD design

There is a drawback in that the efficiency significantly decreases due to the structure where fine dust, which was exhausted and falling, reattaches to the filter by upward airflow. The frequent exhausts also shorten the lifespan of the filter.

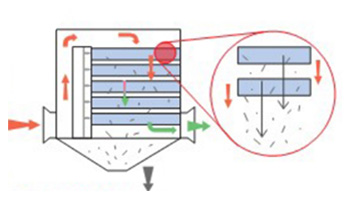

NEW design

Due to the exhausted dust naturally falling downwards along the downward airflow, the efficiency is high. It can drastically reduce the number of exhausts and the consumption of compressed air, resulting in increased filter lifespan and cost savings in maintenance.

Traditional dust collectors use vertically arranged cylindrical bag filters,

making filter replacement and maintenance tasks challenging. Moreover,

they require a relatively large space.

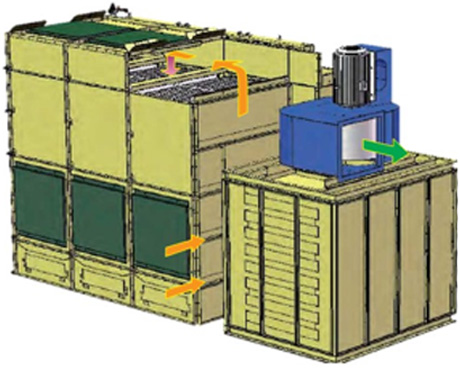

Conversely, On the other hand, Fine Auto System Co., Ltd.'s dust collector

arranges filters horizontally and is equipped with an access door on the side,

making filter replacement and maintenance tasks easier. Furthermore, it can be

installed in spaces up to 40% smaller compared to traditional dust collectors.

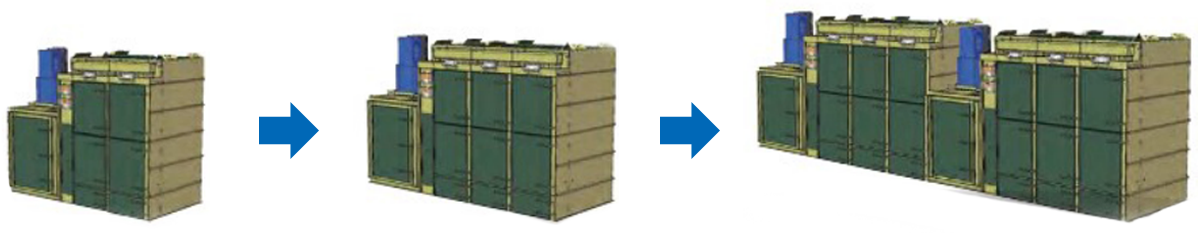

By adding modules according to the work environment, it can produce a variety of output volumes. This approach not only saves additional costs for design changes or custom orders but also facilitates expansion.

AIR PULSE

By spraying compressed air according to the filter's contamination status, the design, which increases the dust removal rate, can maximize both the lifespan of the filter and energy efficiency.

COMEFRI

SIEMENSE

By adopting the durable Italian Comefri fan and the high-efficiency Siemens motor, it is possible to reduce energy consumption costs.

| Size | 5100*2050*3150 | Volume | 560CMM | Filter Array | Horizontal Structure |

|---|---|---|---|---|---|

| Filter Type | Square Bag Filter | Number of Filters | (10*4)*3 = 120EA | Dust collection area | 168,000,000㎟ |

| Dust Collector's Emission Type | Compressed air injection type | Motor | 30KW | Fan | 33600CMH, 2250PA |

| A/C Tower | Cubical Nano Activated Carbon | Carbon Filter | 19x10x8layers=1520pcs | Device | 3mm thick steel plate |

| Application Booth | Medium to Large Booth |

※ Try moving side to side.